Augmenting Construction with Automation and Robotics

The construction industry has long been associated with heavy equipment, high costs, lengthy project schedules, and manual labor. As we continue to see automation introduced into a variety of industries, it should come as no surprise that this industry presents vast potential for transformation. Technologies ranging from autonomous mobile robots (AMRs) to 3D printing to automated fabrication, cutting, and assembly all provide opportunities for improvements in productivity, accuracy, and cost-effectiveness in construction.

The conventional approach to construction hasn’t changed much in recent decades. While equipment has become stronger, more precise, and more flexible in its ability to get the job done, the manual aspect of people performing tasks or directly controlling equipment that does the work has largely remained the same. But with changes in age demographics and increasing demand for commercial, residential, and industrial structures, the construction industry is under pressure to increase performance despite a declining pool of its most important resource — people.

Labor Deficits Persist

Recently, supply chain limitations were among the top factors negatively impacting the pace and cost of construction projects. With many of those issues resolved or improving, the scarcity of skilled labor is again taking center stage as a persistent issue compounding many productivity challenges. Tradespeople from the generation of boomers are exiting the industry faster than they are being replenished, and those coming in need time and experience to reach the proficiency of the ones they are replacing. The effect extends beyond declining productivity: quality of work can suffer, safety can decrease, and overall material waste can grow, impacting project schedules, costs, and results.

What Does Automation Bring to the Table?

Natalie Adams, product marketing manager for robotic software at Hypertherm Associates, believes that in addition to alleviating the labor deficit, robotics and automation can have a meaningful impact on overall productivity, profitability, and waste reduction figures. “Investing in robotics and automation empowers the construction industry to significantly boost productivity,” says Adams. She adds, “This enhancement in efficiency allows builders to meet project deadlines and to fulfill customer expectations within prescribed timelines.”

Incorporating automation brings improvements in quality through increased repeatability and precision. This is particularly evident in applications that involve cutting, welding, or other fabrication. Along with quality improvements come advances in waste reduction — an aspect that Adams sees as “increasingly important as more companies focus on minimizing their environmental footprint.”

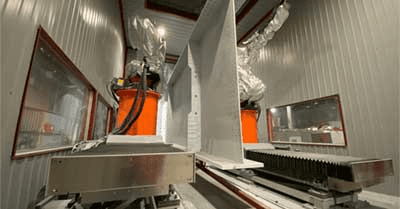

The benefits don’t end there; automation can also improve worker safety. Raise Robotics co-founder Gary Chen highlights the many risks to workers at jobsites: “Tasks such as installing brackets for building facades require workers to be completely or partially positioned on the outside of a building, with safety risks increasing with building height.” By leveraging automation for tasks that pose health hazards, businesses can create distance between human workers and the risk. Giovanni Pucella, general manager of Robexco, notes that with automation, “prefabrication processes can be completed away from the construction site, in safer, controlled environments.” Then fabricated materials can be transferred to the site for installation or final assembly.

What’s the Holdup?

Pucella believes that automation is no longer perceived as the unknown it once was, commenting that “people are no longer afraid of how automation will impact their jobs and are shifting toward an openness to seeking solutions.” And the various benefits brought forward by technology advancement can quickly offset the initial investment required to get started with automation. Future savings can be used to increase company competitiveness, enhance workers’ benefits, or increase profit margins. So with the multitude of reasons for adopting automation, why isn’t the industry rushing to change?

Progress remains limited by a lack of technological expertise and awareness within the construction industry. Aside from a lack of labor in general, those with the experience or knowledge to program, operate, and maintain robotics systems are almost nonexistent. It is critical to understand who will be configuring and operating an automation system. Because the industry doesn’t commonly have specific operators for robotics, the implementation curve can be steep.

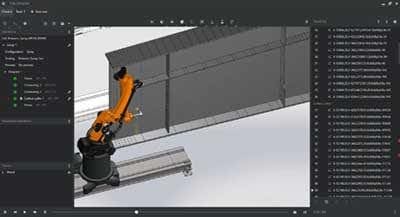

Both Adams and Pucella see the need to create awareness of robotics and automation technologies as an opportunity. They say that to reduce adoption barriers, ease of use is critical to ensuring that customers are successful, despite varying skill levels. One easy-to-use product is Hypertherm’s Robotmaster software. This offline programming tool has an intuitive interface, capable of eliminating the need for operators with specialized robotics skills.

Using Automation to Change Best Practices

For many companies looking to invest in automation and robotics, the first few steps are usually small. Chen suggests “focusing on small, frequent, or repetitive tasks as the best way to ensure early success, as trying to automate too many things or everything all at once greatly increases the chances of failure.” Companies can benefit from working with an automation partner with experience in the applications being targeted. From the start, this will create an environment that takes future needs and goals into consideration, ensuring that solutions are scalable and adaptable, and that investments aren’t limited solely to the initial project.

Construction environments are dynamic and often outdoors, impacted by fluctuating temperatures, precipitation, and other factors, coupled with moving equipment and changes in where supplies are positioned. Utilizing robotics and automation for tasks such as prefabrication provides an opportunity for companies to establish controlled, static environments, free from the risk and variables of an active construction site. Once set up, automated sites are less costly to operate, reducing production and manufacturing costs and opening an opportunity for more consistent quality control. Innovations such as those from Raise Robotics extend quality control and productivity benefits to the jobsite by focusing on repetitive manual tasks that need to be completed with consistent precision.

We’re Only Getting Started

Automation brings with it tools and technologies that are new to the construction industry. Computer vision, machine learning, and artificial intelligence offer the potential to further enhance the industry. But because of the manual aspect the industry has been built on — people performing tasks and directly operating machinery — the expertise needed to program, operate, and maintain robotic systems is largely absent. With technology companies like Hypertherm, Raise Robotics and Robexco supporting the development and integration of tools and solutions that lower barriers and help flatten the adoption curve, the construction industry can transition some manual tasks to automation with confidence that its investments will be worthwhile, generating returns for both itself and its customers.